Product Details

-

Cast iron platform flat series

-

Marble measuring tool

-

3D welding platform

-

Square box/bending plate

-

Series of cast iron flat ruler

-

V-frame series

-

Magnesium aluminum measuring tool

-

Skew instrument series

-

Plug ring gauge series

-

Machine tool pad iron series

-

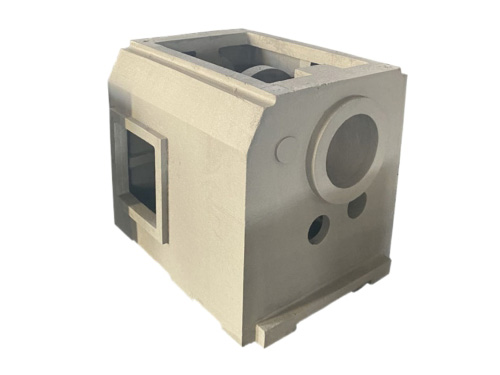

Machine tool casting series

-

Counterweight iron series

-

Cast iron flooring

-

Ground rail series

-

Special wrench series

-

Other series

-

Machine tool inspection measuring tools

-

Haval Festival series

-

Valve series

-

Casting

Gray iron castings

The basic characteristic of high-density molding sand for gray iron castings is that the amount of coal powder added is also relatively low.Therefore,when mixing sand,the following points should be taken into consideration.

①Clay content and mud content.The molding sand with high clay content also increases in strength with higher specific pressure,and the effect of bentonite is usually controlled at 7%to 10%.The sum of effective clay and dead clay in molding sand is equivalent to the mud content,which is generally controlled between 12%and 16%.The high or low mud content can affect the various performance indicators of molding sand.

②Moisture.The moisture in the sand used in the production of lost foam castings is the main factor determining the plasticity and bonding strength of clay.When the moisture content is too high,it is easy to cause a deterioration of the clay bonding force,a decrease in the flowability of the molding sand,and the inability to obtain a uniform casting density.When the moisture content is too low,the sand is not easy to mix evenly,the strength of the sand is low,the brittleness is high,and the moldability is poor,which can easily cause sand sticking defects in the casting.The general moisture content should be controlled to be 10%to 20%higher than the moisture content at the peak of the wet compression strength.

③Original sand particle size.When molding with higher density,the sand mold has a higher density and expands greatly during pouring.Therefore,the original sand particle size should not be overly concentrated.The original sand particles are circular or polygonal,and generally three or four screen sand is selected.

The retesting condition for gray iron castings is that if the first test result cannot meet the mechanical performance requirements of the material,repeated testing is allowed.So,how to verify whether the experiment is effective.

The excellent effect of the experiment can be verified by the following methods:if the experimental results do not meet the requirements due to reasons other than quality issues of the casting itself,the test results are invalid:improper clamping of the specimen on the testing machine or improper operation of the testing machine;There are casting defects on the surface of the sample or improper processing of the sample(such as transition rounded corners,surface roughness and size not meeting requirements,etc.);The tensile specimen fractures outside the gauge length;There are obvious casting defects on the tensile specimen port.In the above situations,samples should be taken again from the same test block or from the same batch of poured test blocks for retesting.

NEWS

NEWS

-

The main function of welding platforms

2022-09-08 05:40:39

-

Measures for maintenance and upkeep of the marking platform

2022-09-08 05:39:16

-

Reference plane inspection and application of cast iron platforms

2021-01-24 11:20:22

-

The centralized method and measurement inspection method for installing cast iro

2021-01-20 09:21:17

-

How to Reasonably Design Reinforced Ribs for Cast Iron Platforms

2021-01-19 09:51:22

CONTACT

CONTACT

—— E-mail:326673342@qq.com

—— Tel/Fax:+86-0317-8383389

—— Phone:+86-18603177396

—— Address:Linzhuang, Haocun Town, Botou City, Hebei Province