Product Details

-

Cast iron platform flat series

-

Marble measuring tool

-

3D welding platform

-

Square box/bending plate

-

Series of cast iron flat ruler

-

V-frame series

-

Magnesium aluminum measuring tool

-

Skew instrument series

-

Plug ring gauge series

-

Machine tool pad iron series

-

Machine tool casting series

-

Counterweight iron series

-

Cast iron flooring

-

Ground rail series

-

Special wrench series

-

Other series

-

Machine tool inspection measuring tools

-

Haval Festival series

-

Valve series

-

Casting

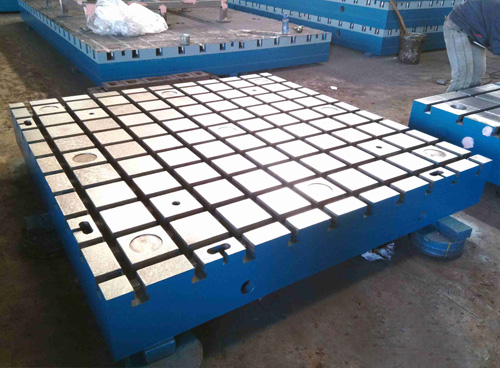

Assembly platform

The assembly platform is suitable for large cast iron flat plates with specifications greater than 4000X8000,as a single cast iron flat plate has a large area and is not easy to transport or install.The method of using small-sized cast iron flat plate splicing is used to complete.This splicing method has no impact on the use of the splicing platform.

Assembly platform belongs to a type of cast iron platform,which is used for mechanical and engine power experiments,equipment debugging,and has good planar stability and toughness.The surface has a T-shaped groove,which can be used to fix experimental equipment.The splicing platform is also used as the installation base for devices.Depending on the device,the structure of the panel of the splicing platform may vary.The splicing platform has T-shaped slots and also has openings.

The material of the assembly platform is generally HT200-300,and there are also customers who require it to be made into ductile iron or cast steel splicing platforms;The specifications of the splicing platform are generally customized by design,as the equipment is different and conventional specifications cannot be suitable.Products with conventional specifications have a small load-bearing capacity and are difficult to withstand the weight of general equipment.

The support method for the assembly platform is that if the installed equipment needs to vibrate,it should be connected to the ground.If the equipment is only installed on the assembly platform for simple measurements,it should be supported by shims or brackets.

The accuracy of the assembly platform is level 0,1,2,and 3,and the general calculation method is as follows:

1.Select the layout form based on the shape and size of the tested splicing platform,and determine the number of segments and bridge deck span for each section:L=where l-the length of the tested section;L-Bridge slab span;N-Number of segments.

2.When measuring with a spirit level,adjust the measured surface to a roughly horizontal position;When using an autocollimator for measurement,the splicing platform is adjusted to be roughly parallel to the instrument's optical axis.

3.Place the bridge deck of the inherent level or reflector on the measured section,move the bridge deck with equal spans and tail connections along the measurement direction,and record the readings at each position of the splicing platform.

4.Process the data according to the segmented calibration results and calculate the flatness value of the splicing platform.

The purpose of assembly platforms is also diverse,for the detection,measurement,marking and other work of some large workpieces.Perhaps people may wonder how to assemble this cast iron platform?Generally,a docking interface is designed on the assembly platform and fixed with bolts.

The assembly platform mainly measures the inspection and measurement standards for the flatness,parallelism,perpendicularity,angle,straightness,and other geometric tolerances of mechanical components of large workpieces.It is also used as a reference plane for machine tool mechanical inspection and measurement to check the dimensional accuracy or geometric deviation of parts.

On the assembly platform,there are interfaces designed and fixed with bolts,which are suitable for inspecting and measuring the flatness,parallelism,perpendicularity,angle,straightness and other geometric tolerances of various large mechanical components.They are also used as reference planes for machine tool mechanical inspection and measurement,checking the dimensional accuracy or geometric deviation of parts.They are also basic tools in mechanical manufacturing inspections such as measurement,inspection,welding,and assembly.

NEWS

NEWS

-

The main function of welding platforms

2022-09-08 05:40:39

-

Measures for maintenance and upkeep of the marking platform

2022-09-08 05:39:16

-

Reference plane inspection and application of cast iron platforms

2021-01-24 11:20:22

-

The centralized method and measurement inspection method for installing cast iro

2021-01-20 09:21:17

-

How to Reasonably Design Reinforced Ribs for Cast Iron Platforms

2021-01-19 09:51:22

CONTACT

CONTACT

—— E-mail:326673342@qq.com

—— Tel/Fax:+86-0317-8383389

—— Phone:+86-18603177396

—— Address:Linzhuang, Haocun Town, Botou City, Hebei Province